Introduction In the field of packaging and structural materials, honeycomb corrugated cardboard plays an important role in modern industry and daily life due to its high durability and impact resistance. It is widely used in industries such as packaging, construction and transportation. Let us help you understand the characteristics, advantages and various applications of honeycomb corrugated cardboard.

What is Honeycomb Corrugated Cardboard?

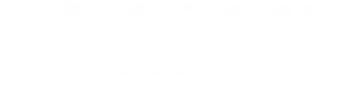

Honeycomb corrugated cardboard is a lightweight, high-strength material named for its structure similar to a honeycomb. It consists of two layers of face paper and a honeycomb core paper in the middle. The face paper usually uses kraft paper or boxboard to provide surface flatness and strength. Core paper: It is honeycomb-shaped and is made of multiple paper strips bonded together to form hexagonal units to provide support and cushioning.

The structure consists of:

- Outer Layers (Facings): Made of strong kraft paper or recycled paperboard.

- Core Layer (Honeycomb Structure): A series of hexagonal cells that distribute weight evenly.

Key Features of Honeycomb Corrugated Cardboard

Lightweight, less material, low cost: Compared with other types of board structures, honeycomb sandwich structure has the largest strength-to-weight ratio, so its finished product has a good performance-to-price ratio, which is the key to the success of honeycomb paperboard. The density of ordinary honeycomb paperboard is about 30~50kg/m³, which is 1/3 of the density of common corrugated paperboard. The price of ordinary honeycomb paperboard is only 60% of wood, 50% of steel, and 66% of heavy seven-layer corrugated paperboard. Due to its light weight, it can bring better economic benefits to users.

Processing and Manufacturing of Honeycomb Corrugated Cardboard

Honeycomb cardboard is produced through specialized manufacturing processes, ensuring strength, consistency, and cost efficiency. Below are the key steps involved:

Lightweight, less material, low cost: Compared with other types of plate structures, honeycomb sandwich structure has the largest strength-to-weight ratio, so its finished product has a good performance/price ratio, which is the key to the success of honeycomb paperboard. The density of ordinary honeycomb paperboard is about 30~50kg/m³, which is 1/3 of the density of common corrugated paperboard. The price of ordinary honeycomb paperboard is only 60% of wood, 50% of steel, and 66% of heavy seven-layer corrugated paperboard. Due to its light weight, it can bring better economic benefits to users.

High strength, smooth surface, not easy to deform: The honeycomb sandwich structure is approximately isotropic, has good structural stability, and is not easy to deform. Its outstanding compressive and bending resistance are important characteristics required by box-type packaging materials. The front of ordinary honeycomb paperboard can withstand a pressure of 2-5kg per square centimeter, which is 5-10 times the compressive resistance of ordinary corrugated paperboard. The bending strength of ordinary honeycomb paperboard is 2-5 times that of reinforced corrugated paperboard and 5-30 times that of ordinary corrugated paperboard.

Good impact resistance and cushioning: Honeycomb paperboard is made of flexible paper core and face paper, with good toughness and resilience. The unique honeycomb sandwich structure provides excellent cushioning performance. It has a higher energy absorption value per unit volume among all cushioning materials. High-thickness honeycomb paperboard can replace the EPS plastic foam cushioning pad that is currently in large quantities. According to research, the compressive strength of honeycomb corrugated paperboard increases approximately linearly with the increase of paperboard thickness and length. The compressive strength of AB fluted honeycomb corrugated paperboard can reach 8.5kgf/cm², A flute can reach 8.5kgf/cm², and B flute can reach 14kgf/cm², which is much higher than the compressive strength of EPS foam plastic.

Sound absorption and heat insulation: The interior of the honeycomb sandwich structure is a closed small room filled with air, so it has good sound insulation and heat preservation performance.

Pollution-free and in line with modern environmental protection trends: Honeycomb paperboard is made entirely of recyclable paper materials, which can save wood instead of wood, replace EPS plastic cushioning pads, and can be fully recycled after use. Waste and scraps from the corrugated box production process can also be die-cut and glued together to make honeycomb corrugated cardboard cushioning pads of various shapes. Even if they are discarded, they can be naturally degraded and absorbed, making them a very good green and environmentally friendly packaging material.

Industrial Application of Honeycomb Corrugated Cardboard

1. Packaging industry: making packaging products such as cartons and cartons, which can be used for cushioning packaging of products in the food, chemical, pharmaceutical, hardware and other industries

2. Transportation industry: making interior decoration materials for transportation tools: such as luggage boxes and partitions of trains, buses and airplanes, improving fuel economy and providing lightweight sound insulation solutions.

3. Construction industry: partition walls and ceilings: used as partition walls and ceilings for office buildings, shopping malls, hotels and other places, with the advantages of light weight, sound insulation, heat insulation and fire prevention.

4. Advertising display industry: display boards and signs: used to make exhibition display boards, billboards, signboards, etc., which can be customized in different shapes and sizes according to needs.

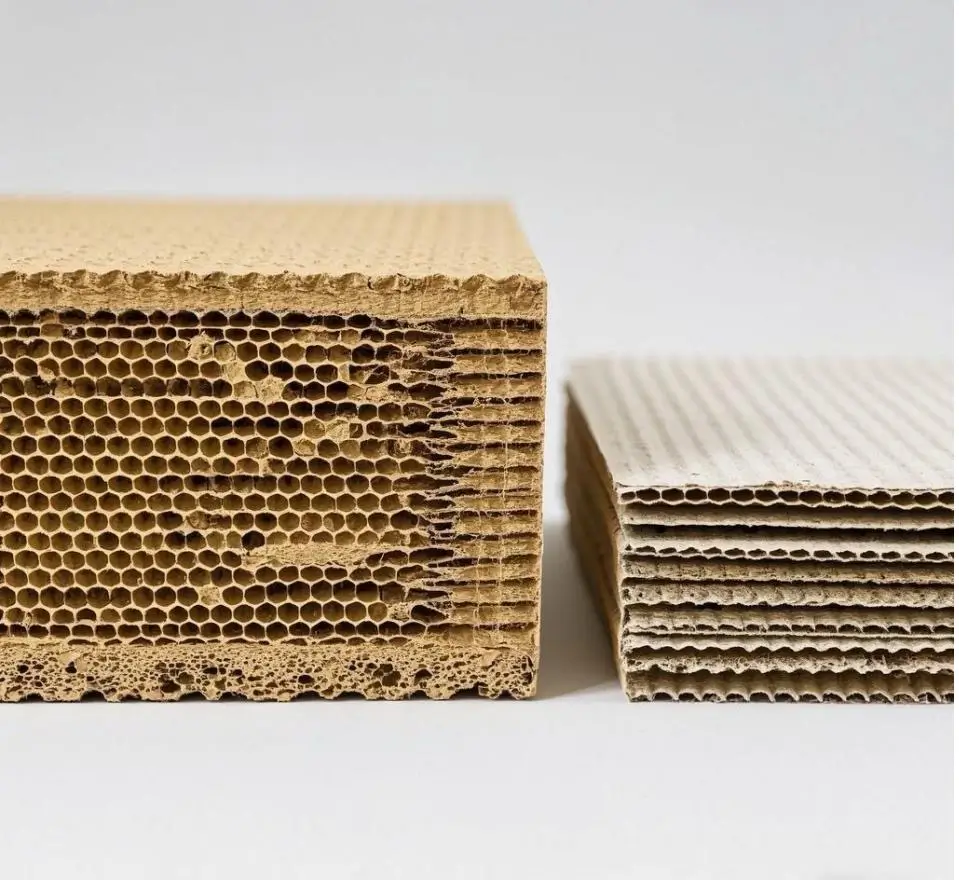

Honeycomb Corrugated Cardboard vs. Regular Corrugated Cardboard

| Feature | Honeycomb Corrugated Cardboard | Regular Corrugated Cardboard |

| Strength | Higher due to hexagonal core | Moderate strength |

| Weight | Lighter while maintaining durability | Heavier for the same strength |

| Shock Absorption | Excellent impact resistance | Good but less effective |

| Insulation | Better sound and heat insulation | Limited insulation properties |

| Cost | Slightly higher but more durable | Lower cost but less strength |

| Eco-Friendliness | 100% recyclable and biodegradable | Recyclable but less structurally efficient |

Summary

As a new type of packaging material, honeycomb corrugated cardboard not only has the characteristics of light weight, high strength and low cost, but also has good environmental performance. Therefore, it has broad application prospects in many fields.